Customized Solutions

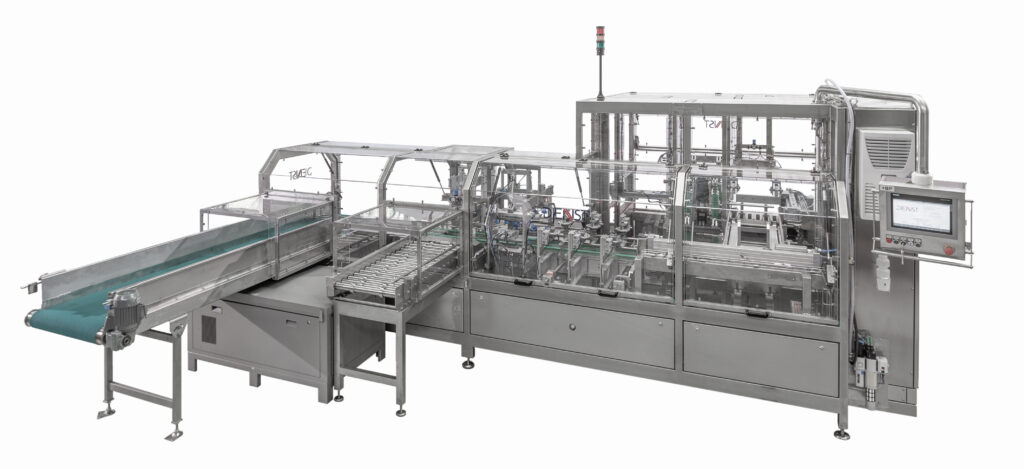

DIENST Vertical Cartoner – Fully automated assembling of pre- glued cartons.

The DIENST VC system automates the process of filling and closing of pre-glued cartons of different types and designs and of different carton qualities.

The cartons are being erected by a rotation system and inserted into a drag chain.

After transportation and closing of the bottom of the carton, it is filled through product specific loading or intake systems. The filled cartons are then being closed and encoded if needed.

Several control mechanisms ensure an efficient operation.

Customer benefits

Flexible adaptation to loading and insertion systems

Intermittent or continuous work process depending on the customer product

Intuitive user interface with self-explanatory display and visualization of the function sequence

Material protection thanks to servo drive movement profile adapted to each format

Permanent data storage of all servo motors with trend analysis to prevent production downtimes

All DIENST models are suitable as stand-alone machines or as integrated components within a packaging line

Simple and reproducible machine settings by saving the setting values

Options

Discover our innovative range of solutions designed to revolutionize your manufacturing processes. Optimize your production and increase efficiency with our advanced options.

Processing of special cartons

Fully automated format changeover of the system, changeover time under 2 minutes

Enlarged magazine for increased cutting capacity, extended autonomy

Extended sensor system for comprehensive quality control

Extended corrosion protection according to climatic requirements

Ejection station for detected faulty packs to avoid production downtimes

Equipped with various coding systems

Multi-zone lighting for fast and localized fault detection

Network-compatible production monitoring incl. integration of third-party machines into the process chain

Equipment for remote maintenance, remote diagnostics, predictive maintenance and visual monitoring

Manual or fully automated folding carton filling

DIENST Sleeving and Banding – Fully Automated Sleeving of Products

The DIENST Banding system fully automates the processes of sleeving and closing meeting highest requirements.

Here the cutting is put on top of the product, which is transported on a conveyor and moves synchronized to the conveyor. The container is then being picked up by an upper shuttle-chain and the side flaps are being folded downward. Separately driven folding systems provide for folding and closing of the aligned flaps on product side or product bottom.

Depending on the requirements, the sleeves can be folded several times, closed with hot-melt glue or encoded if necessary.

Additionally for a secure connection, the sleeves can be fixated to the product by an individual type of glue.

Customer benefits

Material protection thanks to individual movement profiles of the servo drives with overload function adapted to the respective format

Simple and reproducible machine settings by saving the setting values

Airtight welding for the highest hygiene standards

Intuitive user interface with self-explanatory display and visualization of the function sequence

Permanent data storage of all servo motors with trend analysis to prevent production downtimes

Options

Discover our innovative range of solutions designed to revolutionize your manufacturing processes. Optimize your production and increase efficiency with our advanced options.

Enlarged magazine for increased cutting capacity, extended autonomy

Extended sensor system for comprehensive quality control

Ejection station for detected faulty packs to prevent production downtimes

Network-compatible production monitoring incl. integration of third-party machines into the process chain

Extended corrosion protection according to climatic requirements

Equipment for remote maintenance, remote diagnostics, predictive maintenance and visual monitoring

Equipped with various coding systems

Multi-zone lighting for fast and localized fault detection

Manual or fully automated folding carton filling

DIENST decartoning systems

Horizontal unpacker for e.g. butter or similar dimensionally stable products. With a lifting station, razor-sharp cutting tools, a turning device and servomotor-driven product ejectors, we guarantee maximum process reliability with minimum product wear.

At the end of the machine, the unpacked product and the opened carton are placed at an ergonomic working height ready for further processing.

Customer benefits

Material protection thanks to individual movement profiles of the servo drives with overload function adapted to the respective format

Permanent fault monitoring with sensitive disengagement of the sliders in the event of overload

Airtight welding for the highest hygiene standards

Simple and reproducible machine settings by saving the setting values

Intuitive user interface with self-explanatory display and visualization of the function sequence

Permanent data storage of all servomotors with trend analysis to prevent production downtimes

Options

Discover our innovative range of solutions designed to revolutionize your manufacturing processes. Optimize your production and increase efficiency with our advanced options.

Extended conveyor and transport systems

Knife sharpener

Advanced sensor technology for comprehensive quality control

Network-compatible production monitoring incl. integration of third-party machines into the process chain

Extended corrosion protection according to climatic requirements

Equipment for remote maintenance, remote diagnostics, predictive maintenance and visual monitoring

Equipped with various coding systems

Multi-zone lighting for fast and localized fault detection